WGAN-TV | Matterport + SIMLAB SIM-ON + IBM Maximo = Maximo Vision for Asset Management | Guests: SIMLAB SIM-ON Product Owner/Project Manager Michał Szopa and Maciej Guzek, AIUT Asset Management Solutions Manager of Digital Industrial Transformation | Wednesday, 12 March 2025 | Episode: 236 | www.SIMLABinc.com | www.SIM-ON.com | www.WGAN.info/SIMLABonWGAN | @Jedrzej @SimlabSales @SIMLAB

Transcript (Video above)

Are you wondering:

– how to use Matterport digital twins to enhance enterprise asset management?

– leverage SIMLAB SIM-ON to integrate IoT data task management and 3D visualization?

– combine these tools with IBM Maximo to optimize maintenance and operational workflows? Stay tuned. Hi all, I'm Dan Smigrod, Founder of the We Get Around Network Forum:

www.WeGetAroundNetworkForum.com

Today is Wednesday, March 12th, 2025. You're watching WGAN-TV Live at 5: a podcast for digital twin creators shaping the future of real estate today. We have an awesome show for you: Matterport + SIMLAB SIM-ON + IBM Maximo = Maximo Vision for Asset Management.

Our subject matter experts are SIMLAB SIM-ON Product Owner and project manager, Michał Szopa. And AUIT Asset Management Solutions Manager of Digital Industrial Transformation, Maciej Guzek. Michał and Maciej, thank you for being on the show.

- Thank you, hello everybody.

- Yeah, thanks Dan. Great to be here today with you.

- Thank you. Before we do a deep dive into IBM Maximo and how it integrates with Matterport and SIMLAB SIM-ON, let's give our viewers a brief overview of SIMLAB SIM-ON and AIUT. Michał, let's start with SIMLAB SIM-ON.

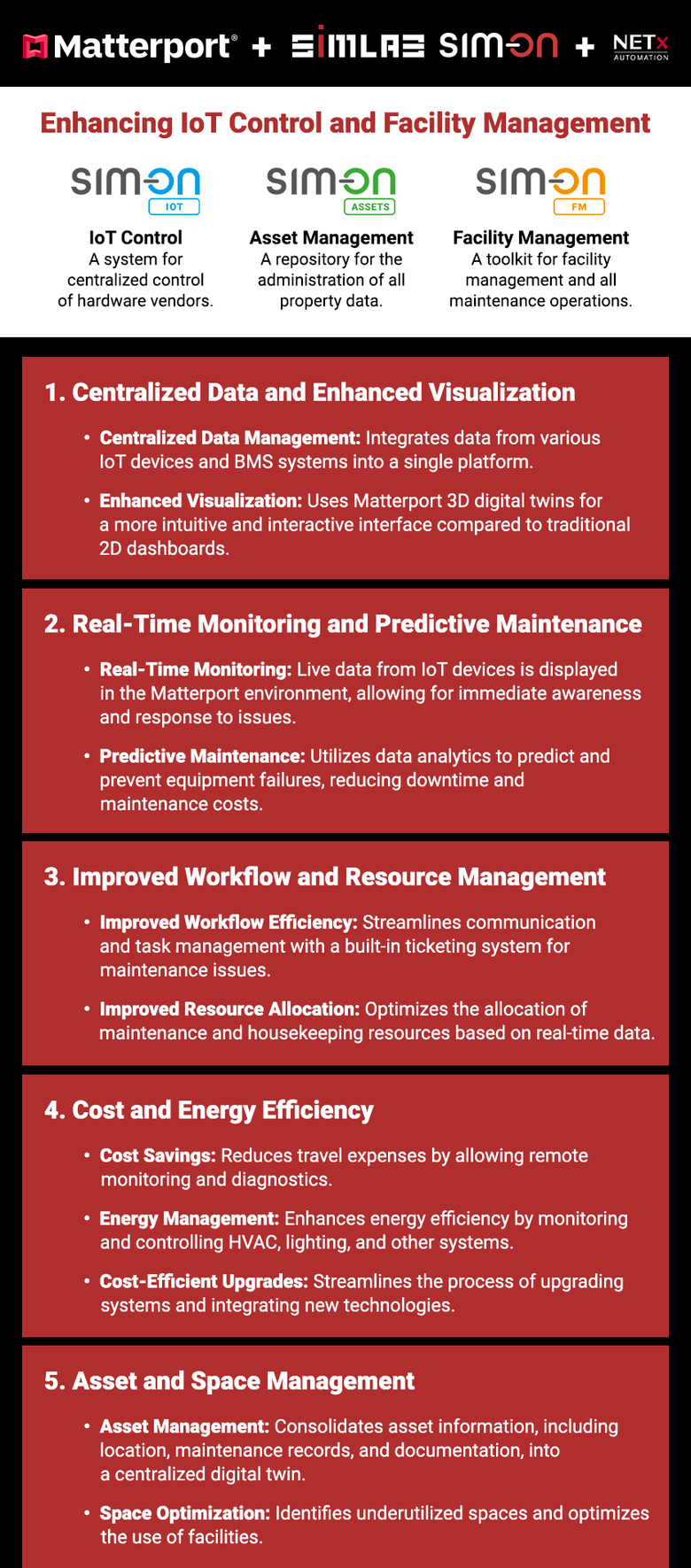

- Okay, thank you Dan for the introduction. And once again, hello everybody and my name is Michał and I'm the product owner in the SIMLAB and responsible for the SIM-ON product, which is the layer of the Matterport adding options for the IoT devices and asset management.

And we have been working with our product for more than five years. I'm in the company four years and I will be pleased to show you today how SIMLAB SIM-ON works together with the Matterport digital twin solution and AUIT and IBM Maximo integration to combine all of the information into the one ecosystem with a very nice and very clear and intuitive interface of the digital twin and virtual walkthrough.

- Thank you, Michał. And we're not going to do a really deep dive right at this moment into SIMLAB, but I will point out for our viewers that we've done many shows with Michał about SIMLAB, SIMLAB SIM-ON, you can see those previous episodes at: www.WGAN.info/SIMLABonWGAN Maciej, for context for today's show, please tell our viewers about AIUT.

- Okay, so thank you. This is the first time that I have a chance to tell you a little bit about what we do. AIUT in general, is an engineering company focused on industry. Is it okay that I can share some slides with you right now, or shall I wait with that?

- Let's wait until we get there.

- Okay.

- But just take another moment at the top line to tell us about AIUT.

- Okay. So we are an engineering company working for industry customers, mainly focused on automation and robotics.

And I'm representing the department which focuses on introducing IT to the plant floors, especially in terms of IT systems for asset management and work management.

- And your relationship to IBM Maximo?

- Yeah, we are an Authorized IBM Partner and what's more, we are authorized to build our own solutions, so to deliver our own systems based on IBM technology. One of them is IBM Maximo, which I would like to show you briefly today.

- And your coverage area for AIUT? I want to say you have a thousand plus employees. AIUT is a large, worldwide organization?

- Yes, we are present from North America, U.S., Canada, up to China, through the whole Europe and Asia. As we work on the plant floors on industry customers.

We want to be just a company around the corner. To be close to our customers, to deliver our services, to deliver our solutions and be as close as possible because, especially, the assets that we deliver, like robots and automated production lines, requires our presence.

- Awesome. Michał, Maciej, for the purpose of today's show, let's assume that our viewers are Matterport Service Providers that have enterprise clients.

They want to learn about Matterport plus SIMLAB SIM-ON plus IBM Maximo, how that combination can help their clients. MSPs have a deep understanding of Matterport, we can make that assumption. I think this would be a good time, perhaps, Maciej if you tell us about IBM Maximo and if it's easier for you to share your screen, that's fine as well.

- Okay. As I already told you quite a lot about AUIT. I will just skip the first slide, but as you mentioned, we are over a thousand employees company, which is specific -- We are a private company, family-owned. We started in 1991 .

And we are focusing mainly on robotics, automation, process optimization for our customers. So production processes, maintenance processes, and asset management. Usually, they are the production lines.

As I understand most of the Matterport users may be focused on facility management. Nevertheless, it's still an asset. So whether this is fleet assets or production assets, we still need to maintain those and take care that they are available and working on proper levels according to some SLAs or KPIs. As AIUT, we support our customers starting from product design.

So even in the first stage, some of our customers show us wonderful products, which are the prototypes.

So our role is to redesign the ideas, the prototypes to become a real product whose production can be automated. Next step, this is designing the production process to optimize it from the beginning for dedicated assets through the factory construction, machine building, delivering the production assets actually through the whole intralogistic, which is a little bit closer to the facility management.

So automated store rooms, vaults and automated transport based, for example, on AMR. So Automated Mobile Robots. So fully automated intralogistic transport up to delivery and implementation of IT solutions.

So this is what my department is responsible for. We integrate this low-level hardware, machines, PLCs, SCADAs with the high-level systems like ERP financial solutions. Moreover, we offer as well the services for the asset management and support operators training and even deliver the workforce together with our partner for our customers.

Based on that, usually there are no blank spots at our customers and there's quite a lot of existing IT systems solutions. Even nowadays, they are quite often like a silo solution.

So our way is to build a whole ecosystem of integrated systems and solutions whenever it's possible. We try to use the existing systems wherever there is a need, we deliver our own solutions.

So we've got a set of our partners, vendors and our own systems that we can use. IBM is one of them and Maximo system, we use the Maximo as a platform actually for asset management that we can build the whole IT solution, data exchange and utilize that to optimize and ensure the production process.

- Let me interrupt. Forgive me, Maciej, WGAN-TV viewers are typically service providers -- Matterport Service Providers -- it's just a little bit too much detail in terms of what the company does. I think we really need to kind of stay focused for a non-tech on what IBM Maximo is.

I understand the context is, there's a robust amount of solutions that AIUT offers, but let's just focus on IBM Maximo in terms of, "I've never heard of it. I'm a Matterport Service Provider. I've never heard of IBM Maximo. What is it? Why does it matter to me and my enterprise size clients?"

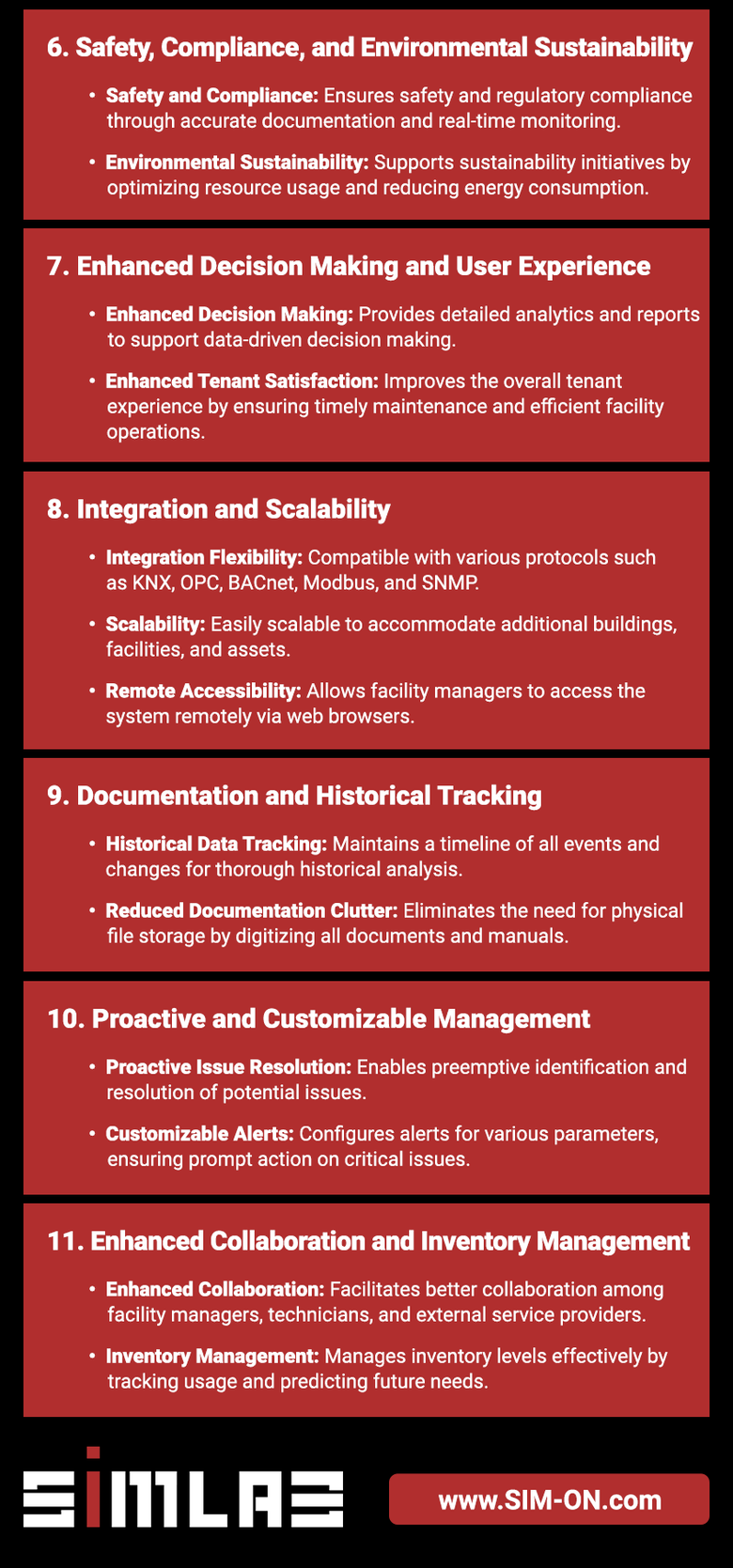

- Simple words, this is the IT platform that can help you to understand and to have a single pane of glass. What assets do you have? Where are they? How they are connected. What needs to be done to keep them running?

So what work needs to be done. Inspections, preventive maintenance, ticketing system for breakdowns. You need to assign what assets and resources you need to perform that work. What employees, materials, do you have? Do you have a contract to replenish your stocks, for example.

Do you have the right competencies on site to do that work? How it's built into the schedules. How it relates to the production plan with all the work that you need to do for the maintenance of your existing assets.

- So Maciej, let's take a mechanical, electrical, plumbing space, an MEP space. Many Matterport Service Providers shoot those kinds of spaces. Can you tell me a story to illustrate why companies, enterprise size companies actually need to understand all the assets that they have in that mechanical, electrical, plumbing space?

- So let's assume that you're sitting at your desk and there is no power in the socket. So what do you do? You need to inform someone that there is a problem. An electrician gets the information that there is a problem in Dan's office.

So I need to understand and find out how the network is connected. So where the socket is connected to which transformer, where the root cause of the problem is, and then try to fix it as soon as possible.

It can all be under the SLA that the system will notify the user, but it's already half an hour and you still don't have your power. So it needs to be solved quickly and something needs to be done there. What's more, to ensure that it will not happen next time.

You probably would like to have some scheduled work, some inspections to go and check specific assets. If there is any problem, it is overheating. For example, we can automate as well and get the readout from the voltage, heat, temperature, and system may notify us that the temperature is rising. So someone needs to go there and check what's going on.

- Can you take it a little bit further? I think what I've heard is kind of two things. First is the ability to remotely see all your assets and what their status is. Presumably through, for example, IoT devices so that you know, the pressure, the temperature, whether power is going to a particular socket, electrical outlet and then something fails.

So that would perhaps be that second case and someone needs to be notified. So I'm hearing a ticketing system. Can you speak a little bit about predictive in terms of how IBM Maximo meets mechanical, electrical plumbing? Maybe describe it as a story?

- So when we want to move from the reactive to the predictive maintenance, that's where we are based on the data that we can get from the IoT devices, from regular inspections and readouts, which can be entered manually as well to the system by the inspector.

And based on that information, we can use them to trigger the business rules, which tells us that whenever the temperature is going above some level, we need to do something.

Right now with more and more data, because we are collecting a lot of data, which is in most cases unused, a lot of that we don't actually know or our customers don't know what to do with all that data, pumping that into the database and into the models which may be AI supported, we can correlate different aspects, different data together to predict the failure dates even.

So we cannot only do the typical preventive maintenance or predictive, but even up to prescriptive maintenance, which based on those models, we predict the failure date of specific assets based on the whole history that we gather into one place.

So this is when we are talking about the maintenance and actually doing work on our assets and assuring that they are working properly. But the first leg before we start that, we need to build this digital twin, which consists of all the information we can gather and in this space, we use IBM Maximo as a central system to integrate all of the data.

So as you mentioned, for example, this power outlet and the problem, where do we have the drawings? The diagrams. How it's connected. The whole network. So this is also the space when we can integrate all that information into one place. We don't have to copy that.

So this is not a master system to store all that data, but we link it as we did it with SIMLAB SIM-ON that we are just making the connections and allow users to switch between the systems, between the solutions, find the right documentation, find the right view and information at their hand.

- So Maciej, is part of that predictive analytics having a lot of historic data regarding that in this example, the mechanical, electrical and plumbing space? Or is predictive analytics really based on manufacturers' information?

- No, usually, we start with the information that is available. So the first point is the technical documentation from the manufacturers.

More and more vendors deliver already pre-trained models to be used on their devices to use such predictions. Nevertheless, it's always case-by-case built history by the customer. So it all starts with the basic information at the beginning, usually, the regular preventive maintenance does the inspection every week or 300 hours of working of such assets.

Then we add some additional data. We gather historical information about the past incidents and failures, and based on that, we train our models to be better and better in predicting the future.

- And the predicting of the future, the predicting of a failure, let's say, of a boiler or a chiller or some other mechanical piece, perhaps based on its vibration is not in a normal pattern. Are we really talking about AI meets the data, is that how that prediction is done?

- Yes, although being an engineer, it's not so easy to use the AI term here because there are mainly mathematical models or correlation models. So we call it an AI, but usually, we take a lot of data which we can quickly calculate and find the correlations.

So to find the root causes of the issues that happened based on the information that we had so next time, we will see it coming, we can predict that probably it will end up the same way. So yes, we may call it as an AI support, but more or less, this is like correlation models mainly.

- Okay, so I think I've heard three themes: First, there's monitoring, overall monitoring of the space. Second, there is this management when something perhaps fails. And third, predicting when equipment will likely fail. Let's take it up one level. Let me see how to ask this question.

"So, I'm a Matterport Service Provider. I have this sense of what IBM Maximo does, but I'm trying to understand it from my client's perspective because I probably wouldn't come in and describe all the features of IBM Maximo. I'd probably come in about why this stuff matters. So could you describe it from the benefits standpoint? I imagine there's some time savings, money savings, and there's a way that you describe from a potential customer's perspective?

- Sure. So as you already said, it's always about the money, but we can save money per se and as well time, as time is money as well. So for money savings, we can optimize the vendor list, the purchasing processes.

We can centralize all the inventory and purchasing, which allows us to monitor, for example, the vendor fulfillment, the contracts to renegotiate contracts. Having all the data, actually what's the volume of our purchases, what's the lead time and negotiating those.

We can optimize the store rooms themselves, knowing which spare parts are used for which assets because the technical documentation usually has a whole bill of materials, but which parts actually do we use. How often? What's the rotation? How many of them do we need to keep in the store to keep our business running?

And saving time means that I have information at the right moment delivered to the right people at the right time. So I can save much time looking for the documentation, finding the right person to do the right work, having the history of work being done, or having the strategies, the work plans actually prepared for typical works.

I can save my time sending the right person equipped with the right tools and spare parts in place to fix the problem. Not just "hey, go there and look what actually happened and then we will see what we need. Come back and we will send the right people there."

Preparing the right schedules and plans for maintenance work. We can optimize them and align to our either production plan or other schedules for the facility. What is the right time to actually perform the right work?

How we can combine different work to be done at the same place or by the same team. So we do it once; not sending them every day to do different work. So I think this is mainly savings.

We've already mentioned the predictions, so knowing that something might fail next week, I can do the checkup today and not have this failure at all.

- So let's focus on just that one example for a moment. And again, I'm trying to think through for Matterport Service Provider, they may only have a sentence or three to entice the interest of their trusted client who's already using Matterport and perhaps, even Matterport plus SIMLAB SIM-ON.

So I want to make a statement and then maybe you can help me further or embellish with it.

So I'm a Matterport Service Provider, I might say something to my enterprise client like,

"Hey, in your mechanical, electrical and plumbing space, do you ever have things that fail and you had no idea that that was going to happen?"

"Yes."

"Oh, would you imagine that you are using a solution like IBM Maximo that can actually predict when those failures are going to happen?

Would that save you a lot of money being able to avoid a potential failure of an important infrastructure item? We were talking earlier about the power going out.

So if power goes out, presumably your productivity of every employee in the space just stops. The heating going out and having the building too cold is going to dramatically affect your building. So being able to..."

Let me actually try it again, is to say,

"Do you have things in the mechanical, electrical, plumbing space that have previously failed and as a result, cost you a lot of money?"

"Yes."

"Now, could you imagine being able to use a platform software that lets you predict those kinds of failures in order to save the money before you have that failure?" Maybe talk on that topic a little bit more? Is that the way to explain that from a Matterport Service Provider to an enterprise client?

- I would add to that some additional questions.

For example:

"do you know which of your assets are the most time and cost-consuming?"

"Do you know which spare parts are actually used and how often to maintain your assets?"

"Do you know and keep track of all the plant maintenance and do you know when it's going on?"

I will share an example from one of our customers in utilities. When there was power down. So they lost the power for a whole building. So first thing, automatically, the generators should start, they didn't.

They missed the fuel. So whose fault is that? Who was responsible to check the fuel level and to make sure that in an emergency there is enough fuel in the generators to provide the power.

So they lost power for several hours, which probably our customers can calculate how much they did cost because there were no strict lines of responsibilities. No one place where they keep track of all their assets and all things that needs to be done.

So we may talk about AI and predicting the future, but in many cases, there are much simpler scenarios and very small issues that can break the whole system down. I mean, the whole business and keeping track of all of that in one place -- IBM Maximo -- may help us to avoid such situations.

- So saving money for potential problems before they become problems. Saving money when something does fail, being able to quickly solve the problem.

And I think what I heard is sometimes, when problems happen, if you haven't had the inventory on hand in your example, the fuel level in the generator, that all these things are trackable and predictable using IBM Maximo.

- Exactly. We are asked many times how to calculate the ROI of such a solution. Actually, it's not so easy because we are preventing failures.

We are preventing the problems. So it's always, you may try to calculate the last failure you had at your facility, at your business, what caused it and how much you would save by preventing that.

And that's the easiest way to show how much you can save having such solutions for asset managements like IBM Maximo for example.

- Yeah, sometimes not so hard. I was at Geo Week 2025 recently. The Dallas Fort Worth International Airport actually talked about in their previous 12 months that the equipment that failed literally cost them $7 million.

And so I was immediately thinking, "well, did they have IBM Maximo as a predictive solution in order to minimize the failures?"

So that one seemed like the ROI would probably be pretty easy to say, "Gee, in the last 12 months, we had $7 million of cost because something or more than something actually failed. And we failed to predict that it was actually going to happen."

- So now, it's the right moment to talk to them about asset management solutions. But before that incident, it would probably be hard to show that such a solution can really be beneficial for them.

But after such an incident, it's much easier to say, "Hey, you could have prevented that. Should they have had the IBM Maximo asset management solution? It probably would not have happened and that's how much they would have saved."

- Yeah, so there's a pain point there that the client either has experienced or hasn't experienced: yet.

- Exactly.

- Okay. So you started to talk a little bit about digital twins and SIMLAB SIM-ON. Before we actually talk to Michał specifically about SIMLAB SIM-ON, was there a piece that you wanted to talk about in terms of IBM Maximo and AUIT and then tied it back to the digital twins and SIMLAB SIM-ON?

- Probably, it would be good to use a demo that we prepared together with Michał. So whenever you say that it's the right time to show you something.

- Yeah, I think this is a good time.

- More than happy to.

- Yeah.

- So if it's a good time. So let me share the screen with you again.

- Excuse me, while Maciej is calling up -- please go ahead and share your screen -- while he is sharing his screen, know that that AUIT website:

www.AIUT.com

While we're on that subject for IBM Maximo:

www.IBM.com/products/maximo

And I will even at this point mention the websites for SIMLAB:

www.SIMLABinc.com

and specifically, the microsite for SIMLAB SIM-ON is:

www.SIM-ON.com

Maciej, we can see your screen, thank you.

- Okay, perfect. So this will be very brief as you said, just to show you some of the points, especially why and where we integrated with Matterport through the SIMLAB SIM-ON solution.

So this is one of our demo installations. It looks very similar to many asset management systems or other systems that we have configured with dashboards based on the business roles. So I've got a lot of KPIs here and drawings showing what the situation is.

So with one throw of my eye, I can see what's going on. Is it okay or not. As my manager used to say, "If it's green, go and get your coffee. If it's yellow, ask your friend to get you coffee because there's work for you.

If it will be on red, forget about coffee, you don't need it anymore because there's a major problem there." So I've got a lot of lists here of the work that it's being documented, recorded in the system, but starting with the digital twins.

So first of all, to understand what assets do I have, where they are, what's the information available. I will switch to one of our assets.

Actually this is a wheel pump that we will see on SIM-ON in a moment.

So I've got a lot of technical data here, basic data from the manufacturer, some of the history from my system, and what's going on here. I can see all the information about the sub-assemblies, the spare parts, and the system can learn by himself.

For example, based on the work history, actually what spare parts I used to work on that asset. So it will build this bill of materials automatically. With new assets, it's quite easy, we've got the full documentation.

Quite often, we are getting the old assets without the proper documentation in place. So such a possibility to get the information automatically within the system, it's quite beneficial. I can assign some safety plans here.

The hazards, precautions, logout, tag outs, procedures. I understand it's not a time here to show all of the details. I would love to show a little bit more. I can go through weeks around the IBM Maximo showing that. But I've got the whole technical specification.

The documentation I've mentioned, we can have it all at the one place. It can be as well on the mobile solution. So I can get all of that on my phone or tablet as well. And what's more important, I've got all the work history, actually what work was done, what's planned on the assets and how we can utilize that information.

I will switch to work in a moment, but before that, I will show you why we actually integrated IB Maximo with SIMLAB SIM-ON and Matterport through the SIM-ON solution.

Because as you can see, this is a lot of text data. There are documents, but for many engineers, operators, technical guys, they said, "But I would like to see more visuals of where I can find it? What's around?"

Because I can see the structure that my pump is part of some bigger assets and the motor is a sub assembly of the pump about what's surrounding where it's installed. And that's why we can use Matterport and SIMLAB SIM-ON for that.

As you can see, I can have multiple models and multiple scans attached to one asset. So I can have multiple views of this pump.

So right now, I moved automatically to the SIMLAB SIM-ON and pointed straight to my pump.

So I can actually see where it is, what's surrounding, and how it looks. Michał will show you a little bit more in a moment about SIM-ON itself and how it looks from the SIM-ON user point of view.

But from my point of view, as an asset manager, I can see all my stuff here with all my assets pointed and be able to go back to all that information that's stored within IBM Maximo, with the documentation, some instructions, everything in one place. So from my point of view, as a guy who's responsible for implementing such solutions, it doesn't really matter how many IT systems we will use.

I have one place with my assets database that I can integrate all of that information, all of the different systems to do that.

When I want to look into the specific information about the work, because this is as well, the place where I can save quite a lot of time are the automated work order generators.

Because based on the business rules, whether it's predictive, preventive or using the AI, we predict the failure. The system can automatically get all the information into one place, and attach a proper job plan.

This work order actually I'm showing to you was generated automatically by the system. So no user interaction before the time that we can say it right now.

So I've got the instructions, what needs to be done, what qualifications I need, employees I need to perform such work, whether there are any materials I need.

- So excuse me, Maciej, I think really again, for the purpose of Matterport Service Providers, I think we've probably made the point that IBM Maximo could make your eyes glaze over with the user interface design. And I think we're about to jump in to say, "we can take that same information..."

And Michał, how about you pick up, if you don't mind, Maciej, let Michał pick up and talk about the user experience. I think that would be helpful for Matterport Service Providers to say, "Okay, all that technical data of the way it was presented makes my eyes glaze over. Here's a different way, it's the same information just presented differently." Michał.

- Yeah, thank you, Dan. Thank you, Maciej. And yes, imagine the situation that there is a customer and have the IBM Maximo in a big factory, for example, and have 100,000 different assets.

Yeah, and some new or some not so experienced guys come up into the work and need to find, okay, and some pump is broken, yeah. And in the space, we have some 100 pumps, yeah.

And adding to our solution into the IBM Maximo, whereas everything inside from some very technical and detailed point of view, he can very easily find and locate the particular asset, the particular pump into the space. If there is of course, the Matterport scan.

And it is also a good opportunity for Matterport Service Providers to expand their own business, yeah.

Because even if somebody right now has IBM Maximo, they can come there, "Okay, you have Maximo, great, do you have the Matterport scan?" "Oh no, what is the Matterport?" This is a digital twin where you can very easily find your asset from the IBM Maximo inside the digital twin.

- So Michał, again, let's assume our audience, Matterport Service Providers, our audience, totally intimate with Matterport.

So let's think about this and maybe even to some extent familiar with SIMLAB SIM-ON, let's take it to the next extent in terms of where IBM Maximo plugs into that equation. Matterport plus SIMLAB SIM-ON. Now, let's see how plus IBM Maximo fits in.

- Yeah, I can show how it's worked in our software. And I will share my screen and show you the demo.

Okay, I hope you are seeing my screen right now. And I'm going from the dashboard into the 3D space and opening the full screen because that's yeah, a little bit better view and okay.

And we have here, our software with the layer of the IoT devices, which is also part of the SIMLAB software, but it's not today's case, I'm only mentioning the possibility of connecting the IoT devices and having it into the 3D space. But our main goal right now is the assets.

And for example, we have, this is the ventilation centrals inside some food factory where we have some assets, yeah.

And we know that this manometer for example, is the part shown in the existing IBM Maximo infrastructure.

And we can add it, the tag on top of that and with the name, with all the information about that and we can edit and here, we have the place where we can add the IBM Maximo link on top of that.

And we have the two options: we can add from the existing, because after we connecting into the Maximo, we can import all the links inside SIM-ON and then pick it from the previously imported links or adding the new one where we have generated the tree which is representing the structure from the IBM Maximo site, yeah. In this particular case, I see this one is already linked and I can go back from the adding from the existing and I have here somewhere, okay, this one and I click it, add it, save changes.

And right now, I have it connected between our software into the IBM Maximo where I can very easily and very quickly go logged in into the Maximo site and I have all the information about the many materials or some gouge inside the IBM Maximo software where I have much more information than only this, what we have in the SIM-ON site.

And we have the same situation for many, many other different assets, for example, some voltage elements where we also have the possibility to go inside IBM Maximo and see the details according to the particular asset.

- So Michał, I think that this might be as well a nice scenario that Dan was asking, if you could go through this panel that you have been before, because that's when we start from the Matterport scan.

So we've got our 3D visualization, but we need to know more about our assets. So thanks to SIM-ON, I can automatically get the IoT readouts.

I can get the basic documentation, but if you'd like to see, what's the history of that asset, when it was installed, by whom, whether it's under warranty, what spare parts are needed to work on that. That's the moment when we can use IBM Maximo for that.

- And in the opposite way as well, yeah. If we have everything in IBM Maximo, we can also go SIM-ON and see the location in the real world. It's combined together to give the customer or the user a better experience and a much more intuitive way to find the information that are necessarily for them. I'm correct, Maciej?

- That's true.

- Okay.

- All right, so okay. I'm going to represent Matterport Service Providers here and see if I can have a little takeaway here. In fact, first I want to ask you, Michał. The client is already using Matterport ...

Perhaps let's take the scenario that the client already has IBM Maximo too. How hard is it to bring the IBM Maximo assets into a Matterport digital twin using SIMLAB SIM-ON? What's that process look like?

- Right now, the process looks like that we need to have the representation of the asset inside SIMLAB SIM-ON.

For that, you need to create the asset into the SIM-ON site and then link it with the same representative asset into the IBM Maximo site as I was showing you a couple of minutes ago, yeah. But-

- Is that sort of like in the Matterport tagging experience where you've added a tag to each of the assets?

- Yeah, in a very similar way.

- Call it SIMLAB SIM-ON tags. Stay with me here. So the tags, so we go through that mechanical, electrical, plumbing space, we add tags within SIMLAB SIM-ON, then bring in the IBM Maximo and then make the link to each of the assets. Is that what I'm hearing?

- Yeah, it's exactly that kind of way. But it's the first phase of our integration. We are thinking about the integration a little bit deeper into some nearest future that everything from the IBM Maximo can be imported automatically into the SIM-ON and only one thing is to pick the already imported asset from IBM Maximo and put it into the place, into the Matterport 3D space.

It's also very similar to the tagging into a Matterport tour that if you have some tags already created with Matterport MatterTags, the only one thing is it's the plus of the position into the Matterport 3D space and that's it.

- Okay. So for my clarification, let me just see if I understand this. What's coming soon is the ability to import all the IBM Maximo assets into a Matterport space through SIMLAB SIM-ON and the only thing that needs to be done then is to drag the pin location to the correct asset?

- Exactly, exactly.

- Okay, great. Today is Wednesday, March 12th, 2025. Is there a timing that you can give us for that import feature?

- We are counting that we'll be in some up to two months from now. Okay.

- This kind of possibility.

- So April, May, so let's call it, summer 2025.

- Something like that.

- The ability to import the IBM Maximo experience within a Matterport space using SIMLAB SIM-ON.

Maciej, talk about your services as it relates to AUIT in terms of where you fit in, in what Michał was just describing in those two phases, how it happens today and how it happens in the future.

- First of all, we started with this first functionality to prove that it's working and we usually would like to develop our solutions based on the customer requirements. So most of what Michał already said is on our list because we can see that it's needed on the market.

Nevertheless, we've got quite a few other ideas because I would like to see my work orders, my tickets as well in Matterport 3D scan.

Next thing would be a possibility to raise tickets and create work orders straight from the scan so I can pick up the asset on a 3D scan and raise the ticket automatically straight from there.

And so then we may use this 3D visualization as my asset structure interface for the user. So this may become the main interface for the user to see it in a visual way, where there are the problems, record new problems to get all the data straight in SIMLAB SIM-ON.

- So I think part of what I'm hearing is that, let's say, a facilities management person, a facilities manager who is using IBM Maximo may be totally comfortable with the dashboard that you showed, Maciej, but for the rest of the world, who is his visual and it doesn't have the knowledge of that minutia, that it may be way easier to look at a visual container of the content which is Matterport, that three-dimensional model and that it is SIMLAB SIM-ON layer on top of Matterport that enables that to be possible.

So you kind of have the best of two worlds, if you want the IBM Maximo dashboard, you get that.

And if you'd rather simplify it so anyone anywhere in your organization can be looking at the facilities, you can present that as a Matterport digital twin. Maciej, Michał, is that fair to say?

- That was the main idea behind this integration. Because thanks to that, as you mentioned, we add this visual aid to IBM Maximo, which has a lot of data which supports the business processes.

From the other way, we add some life of the processes to the Matterport scans because it's not just to show you the fixed state where everything is, but we have this life behind it.

So all this work history, all this business processes, people responsible for each asset so they know what to do, where it is, how it connects and relates to another. So in my opinion, both of the worlds will benefit from that, that we will get, as you mentioned, the best of the breed in both cases.

- And Michał, I would ask if you agree with that. I just imagine the answer is, yes! Is that anyone who wants to use the Matterport tour to visually see where their assets are located, it sounds like it'd be way easier.

Maybe, what I would share is just a little metaphor, I had some friends that were starting a restaurant and they were showing me their blueprints and I had no idea what I was looking at, but show me a CAD model of what that looks like or the equivalent of a Matterport tour that I can walk through this space.

That's what we're talking about for the people -- for the rest of us who need a visual way to experience a space Matterport plus SIMLAB SIM-ON enables all that data that's in that IBM Maximo database to be presented visually to actually understand it visually. Badly said, maybe you want to take it from there, Michał.

- I don't know what I can add because you fulfilled the topic very loud and clearly and I completely 100% agree with you and Maciej because the visual representative and the interface that you can see the exact place is, in my opinion, also the best way how we can present the location of the data. It's great, yeah. In my opinion as well.

- Yeah, thank you. So when you showed that space, I think you said that it was a food processing factory.

- That was the ventilation centers in the food processing factory, yeah. That was the air changing place with the filters and everything because there was some, I think this is the solid factory where there's also some gasses inside the boxes and that needs to be replacing the very English word I am missing very rapidly.

- I totally get it. I can imagine though a facility like that could easily be, forgive me, I'm going to say it in an American way, half a million square feet, a huge factory, seems like AR fits in here somewhere of wayfinding, is that a feature of SIMLAB SIM-ON?

- Not yet, but we are also working on that, that we can also make some wayfinding into the place, yeah, using your mobile phone, for example, where you're opening the mobile application and synchronizing the scan with your exact location and then into the screen of the mobile phone, the wayfinding to the asset, for example, from the IBM Maximo as well, it will be possible.

And also to add some workflows on top of that. If you are going inside that, you can see what next steps need to be done to, for example, fix the problem, if the changing the pressure and then open or close some valves and the next step and the next step and the next step, yeah.

It's also in our focus right now in development .

- So I think I heard two things on AR coming: One is the wayfinding. So I think in the example where Maciej said the equipment that failed automatically generated a ticket and that might, let's say, if it went to the air handler specialist that needs to deal with that particular problem.

He or she may not know in that ginormous factory, which air handler just failed, but coming at some point with SIMLAB SIM-ON is wayfinding so that that field tech looking at their smartphone would just 'follow the yellow brick road' to follow the path that's showing how to get to the air handler that has failed.

- Exactly, exactly.

- And then second, I think what I heard is that if that air handler manufacturer or that air handler field tech service had an AR feature that overlaid the air handler could show instructions on what actually needs to happen.

So if it was a new feature, it was a new service problem and the tech wasn't familiar with it, the AR might actually help facilitate, making the fix in the field rather than having to make calls to someone else to say, "Hey, I can't figure this out."

- Yeah, but this procedure, the instructions also, will be possible to add from our site, yeah. Some senior engineer can make the instruction, yeah.

Okay, if something is wrong, you need to check this. If the pressure is low, you need to open this valve and so on, yeah.

Everything can be created inside our software that does not need to be only limited to the manufacturer that allows such kind of instruction. It can also add some engineering technical responsible person into the customer side.

- Was I hearing a third feature of AR, which is live support overlay from a subject matter expert that could be overlaying AR to actually show how to fix the problem?

- We are also thinking about that, but I think the next phase after the AR will come.

- Okay.

- First two, that will be the workflows supporting the AR and the wayfinding to the place where the problem is.

- Okay

- Or not even problem because the AR can be also be useful for the wayfinding in some, I don't know, shopping mall or some other kind of-

- Yeah, yeah. Let's stay focused on the mechanical, electrical, plumbing, the manufacturing, warehousing, warehouses, manufacturing.

Today again is Wednesday, March 12th, 2025. Michał, you're the SIM-ON Product Owner, the Product Manager, what's the timing on AR wayfinding?

- AR wayfinding, it will be one quarter. Also, somewhere in the summer that will be appearing in SIM-ON.

- Summer 2025.

- Yeah.

- So before we say bye, we're visiting with Matterport Service Providers. We've had a chance to hear about IBM Maximo SIMLAB SIM-ON, the combination of Matterport + SIMLAB SIM-ON + IBM Maximo.

I think even to add yet another integration which would be AUIT in order to help facilitate this from a systems integrator standpoint, IT, if that's the correct way to say it, Maciej.

- Yeah, that's right.

- Yeah. So what would be the takeaways from today's show for a Matterport Service Provider that is intimate with Matterport, is going to perhaps go back and look at some of the WGAN-TV shows about SIMLAB, SIM-ON:

www.WGAN.info/SIMLABonWGAN

I'm just trying to understand what the takeaways --

I have trusted relationships with clients where I've scanned MEP spaces -- mechanical, electrical, plumbing spaces -- I've scanned warehouses, I've scanned manufacturing facilities, large spaces and I have trusted clients.

What are the takeaways from each of your perspective of today's show that that Matterport Service Provider, if you can only maybe tell them 30 seconds worth to summarize, what would that be, Maciej?

- Well, I would say, if you already have the Matterport scan, let's use it to support your business processes. Let's use it to support the work that needs to be done to integrate it with the digital twin or use it to build a digital twin based on that digitalization model.

Because the full digital twin actually, it's not just the digital model that we are having, but it's related with the processes, with the business rules that we are using on our business.

- Michał.

- Yeah, exactly. Maciej, the digital twin, needs to believe. Yeah, it's not only the model, which is okay, we have a Matterport model, but nobody is using it because it’s (only visual without data).

It is need to believe and need to be added on top of the model, the information from the IoT sensors, the information from the asset database that some other features that will be very useful for daily operating of the facility for the facility manager, for the technical operation staff, for even some cleaning ladies or cleaning services.

Whereas there is also the possibility to use the digital scan on top of that, the data from for example, the IBM Maximo.

- And I'd add one line for Matterport Service Providers, think of Matterport tours as a tool and perhaps, think of Matterport plus SIMLAB SIM-ON plus IBM Maximo as a solution that helps monitor, manage, and predict in order to save lots of money and save lots of time .

And that, I would say is the "Maximo vision for asset management" that we were trying to tie all this together. Maciej, thank you for being on the show today.

- Thanks for the invitation. It was a pleasure to visit on WGAN-TV.

- Thank you. And Michał, thank you for being on the show today.

- Thank you, Dan. That was a pleasure like always, it's not the first time, we know each other a little bit and thank you to the whole audience for today's show, thank you very much.

- Thank you. We've been visiting with SIMLAB SIM-ON Product Owner and Project Manager Michał Szopa, and AUIT Asset Management Solutions Manager of Digital Industrial Transformation Maciej Guzek.

I'm Dan Smigrod, Founder of the We Get Around Network Forum and you've been watching WGAN-TV Live at 5. |